Hydroblaster High Pressure Water Jet Pumps For Airport Rubber Removal

-

Highlight

hydroblaster High Pressure Water Jet Pumps

,Airport hydroblaster pressure washer

,Rubber Removal hydroblast pump

-

Core ComponentsEngine Triplex Plunger Pump

-

PressureSuper High Pressure

-

ApplicationRust Removing From The Steel

-

PowerMotor Or Diesel

-

Warranty1 Year

-

ColorBlue

-

Max.working Pressure950bar

-

Water Flow40L/min

-

Place of OriginChina

-

Brand NameLIFENG

-

CertificationISO9001:2015

-

Model NumberLF-40/95

-

Minimum Order Quantity1 unit

-

Price10000-25000 USD

-

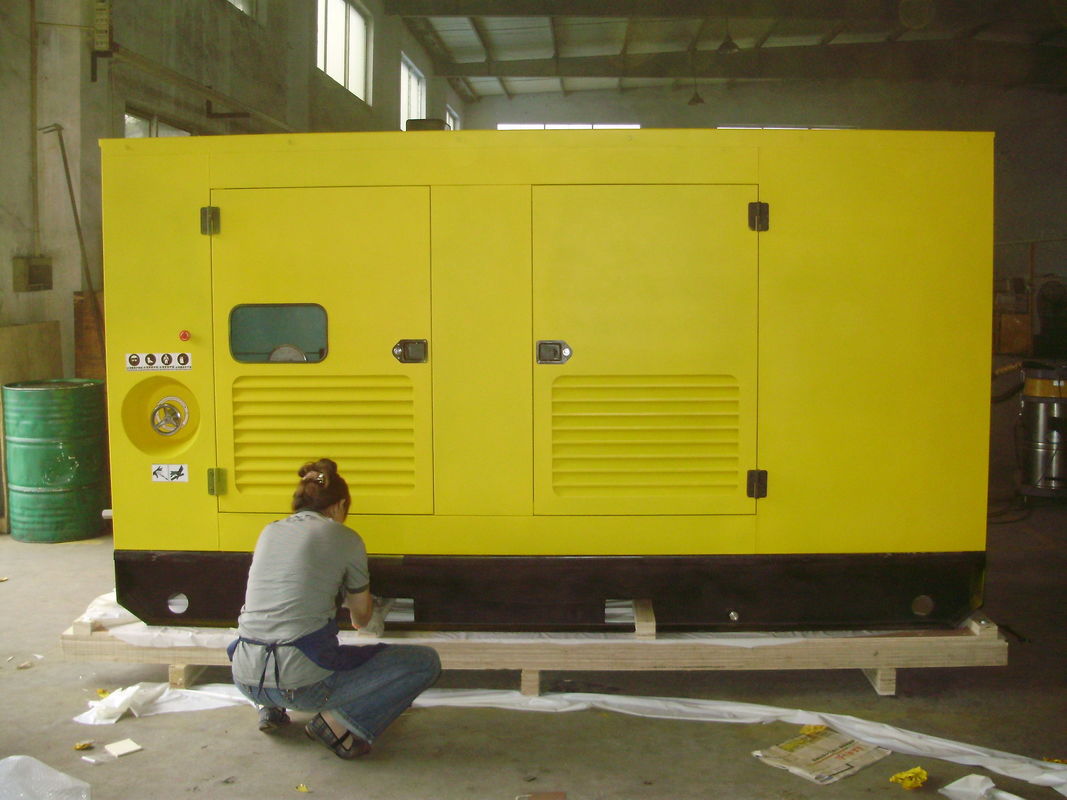

Packaging DetailsPacked by non-fumigation wooden box

-

Delivery Time40 working days

-

Payment TermsT/T, Western Union, MoneyGram

-

Supply Ability300 units per month

Hydroblaster High Pressure Water Jet Pumps For Airport Rubber Removal

Industrial High Pressure Water Jet Pumps Ultra High Pressure water Hydro Blaster for Airport Rubber Removal 1150bar

Details:

1.Power end crankshaft housing is made by the cast iron.it is stronger than the aluminium alloy housing.

2.Cross head is made by the Babbitt hard alloy.it has a long working life for industrial design.

3.Hydraulic end pump head is made by the hard alloy 40Cr.it can work continuously for cleaning jobs.

4.All hydraulic end is desgined for easy uninstall,so it is easy to fix when the parts broken.

5.For some outdoor use purpose,we can make it driven by the diesel engine or the gasoline engine.

Features:

1. High pressure triple plunger pump ( Reciprocating plunger pump, Easy maintenance pump head )

Pressure: 500bar to 1500bar

Water flow: 40 LPM to 80 LPM

2. Engine: diesel engine or Electric motor drive. customer can choose the one they prefer

For diesel engine: Brand has two: WeiChai and Cummis

For electric motor, Brand is SIEMENS or HUALE

3. Pressure regulating valve: 0~ 1500bar. easy to be adjustable.

4. Safety valve: High pressure Rupture Disc valve

Industrial High Pressure Water Jet Pumps Ultra High Pressure water Hydro Blaster for Airport Rubber Removal 1150bar

Characteristics as below:

| MODEL | PRESSURE | WATER FLOW | POWER | Plunger Diameter | STROKE |

| Bar | L/min | KW | mm | mm | |

| LF-256/15 | 150 | 256 | 75 | 55 | 70 |

| LF-195/20 | 200 | 195 | 75 | 48 | 70 |

| LF-164/24 | 240 | 164 | 75 | 44 | 70 |

| LF-135/30 | 300 | 135 | 75 | 40 | 70 |

| LF-110/35 | 350 | 110 | 75 | 36 | 70 |

| LF-98/40 | 400 | 98 | 75 | 34 | 70 |

| LF-87/45 | 450 | 87 | 75 | 32 | 70 |

| LF-76/50 | 500 | 76 | 75 | 30 | 70 |

| LF-66/60 | 600 | 66 | 75 | 28 | 70 |

| LF-57/70 | 700 | 57 | 75 | 26 | 70 |

| LF-50/80 | 800 | 50 | 75 | 24 | 70 |

| LF-40/95 | 950 | 40 | 75 | 22 | 70 |

| LF-34/115 | 1150 | 34 | 75 | 20 | 70 |

Product Description

Industrial high pressure washer is an equipment which is used to clean the surface of objects,the machine with high pressure water jet by means of a power device. It can peel off the dirt ,wash it away to achieve the purpose of cleaning the surface of objects. Because it uses high-pressure water column to clean dirt, high-pressure cleaning is also recognized as the most scientific, economic and environmentally friendly cleaning method in the world compare to the chemical cleaning.

Features

-

This machine is made up of mainly by high pressure reciprocating pump, power units and cleaning accessories etc.

1) High pressure reciprocating pump: the pump is horizontal triplex plunger pump, driven by electric motor, made up of by power end and fluid end.

- Power end: it is made up of by belt pulley(couplings), crankshaft and connecting rod etc. Electric motor or diesel engine,or gasoline engine driven the crankshaft and reduces its speed, and crank link mechanism will change whirling movement to straight line reciprocating movement.

- Fluid end: it is made up of by plunger set, high pressure cylinder, pump body and water input and output valves etc. High pressure cylinder is fixed on crankcase while connecting rod drives plunger to do reciprocating movements, which make volume in cylinder do cyclical change. When plunger is in-sucking stroke, the volume in cylinder increases, water output valve closes, local vacuum is formed. Working media enter into high pressure cylinder by going against water input valve under high atmospheric pressure. When plunger is in discharging stroke, water input valve closes, and plunger transfer the working media to pump body by water output valve, to pressure regulating valve, finally to high pressure spray gun by high pressure hose.

Applications

The pumps are widely used in oil refinery pipes cleaning, heat exchangers pipes cleaning, ship hull cleaing,oil paitings removing,rust removing,etc.

Meanwhile, our pumps also can be used for the fuel pipelines pressure testing,gas steel bottles explosion pressure testing,all kinds of the tubes pressure explosion testing, and so on.

the below are some of our customers photos who came to our factory:

As a 40 years old manufacturing factory,we have many customers from all over the world,

![]()

![]()

![]()

![]()

![]()

Foreign cusomers give us comments:

![]()

FAQ

Industrial High Pressure Water Jet Pumps Ultra High Pressure water Hydro Blaster for Airport Rubber Removal 1150bar

Q1. Are you a manufacturing factory or the trading company?

A: we are a 40 years manufacturing factory.

Q2. Do you have any MOQ limit for the order?

A: Low MOQ, 1pc.

Q3. How do you ship the goods and how long does it take to arrive?

A: Ship by sea shipping.

Q4. How to proceed an order for the product?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly:we sign a contract

Fourthly We arrange the production.

Q5. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.

Q6: Do you offer guarantee for the products?

A: Yes, we offer 1 years warranty to our products.