Explosion Proof Pressure Washers High Pressure Pump Unit For Sewage And Slurry

-

Highlight

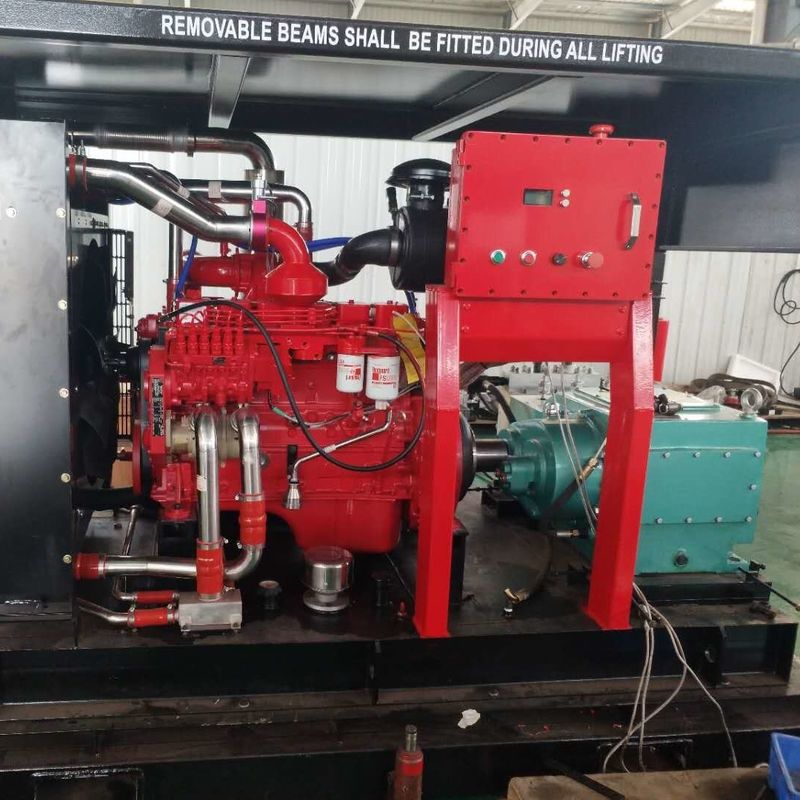

Explosionproof High Pressure Pump unit

,Explosion Proof High Pressure Pump

,Explosion Proof Pressure Washers

-

Product NameExplosion Proof Pressure Washers High Pressure Pump Unit For Sewage And Slurry

-

PowerDiesel

-

PressureHigh Pressure

-

UsageWater,Sewage And Slurry

-

FuelDiesel

-

StructureGear Pump

-

Max.Working Pressure800bar

-

Water Flow50L/min

-

Place of OriginChina

-

Brand NameLIFENG

-

CertificationISO9001:2015

-

Model NumberLF-50/80

-

Minimum Order Quantity1 unit

-

Price10000-100000 USD

-

Packaging DetailsPacked by non-fumigation wooden box

-

Delivery Time30 working days

-

Payment TermsT/T, Western Union, MoneyGram

-

Supply Ability50 units per month

Explosion Proof Pressure Washers High Pressure Pump Unit For Sewage And Slurry

Explosion Proof High Pressure Pump With DNV Lifting FramePump High Pressure Pump Unit

Details:

1.Power end crankshaft housing is made by the cast iron.it is stronger than the aluminium alloy.

2.Cross head is made by the Babbitt hard alloy.it has a long working life for industrial design.

3.Hydraulic end pump head is made by the hard alloy 40Cr.it can work continuously for cleaning jobs.

4.All hydraulic end is desgined for easy uninstall,so it is easy to fix when the parts broken.

5.For some outdoor use purpose,we can make it driven by the diesel engine or the gasoline engine.

GUARANTY OF QUALITY

We offer products of our own design and production and we guarantee it is high quality. A quality control of performed works is one of the main advantages of our Company. Important components of effective work: high qualification of our engineers, strict implementation of technical standards, application of quality materials, use of the most modern equipment and software.

Strict materials incoming (quality) control and acceptance tests

Laboratory and bench testing

100% compliance with technology, international standards

Application of the most modern high-tech QC tools

All manufactured equipment passes bench and field tests

International quality level

Positive feedbacks from our customers

It is extremely important for us that all our customers are 100% satisfied with the quality of our work!

INNOVATIVE AND TECHNOLOGY LEADER

Our mission is to continuously innovate, develop and offer the most efficient equipment for our customers.

Own design office

Technology Innovation Center

The of Companies employs more than 100 qualified and experienced engineers, designers and technicians

Own laboratory and test benches

Operative analysis and adjustment of design.

Explosion Proof High Pressure Pump With DNV Lifting FramePump High Pressure Pump Unit

Characteristics as below:

| MODEL | PRESSURE | WATER FLOW | POWER | Plunger Diameter | STROKE |

| Bar | L/min | KW | mm | mm | |

| LF-128/12 | 120 | 128 | 30 | 40 | 66 |

| LF-92/18 | 180 | 92 | 30 | 34 | 66 |

| LF-72/22 | 220 | 72 | 30 | 30 | 66 |

| LF-62/25 | 250 | 62 | 30 | 28 | 66 |

| LF-54/30 | 300 | 54 | 30 | 26 | 66 |

| LF-46/33 | 330 | 46 | 30 | 24 | 66 |

| LF-38/40 | 400 | 38 | 30 | 22 | 66 |

| LF-32/50 | 500 | 32 | 30 | 20 | 66 |

| LF-26/60 | 600 | 26 | 30 | 18 | 66 |

| LF-128/22 | 220 | 128 | 55 | 40 | 66 |

| LF-92/31.5 | 315 | 92 | 55 | 34 | 66 |

| LF-72/40 | 400 | 72 | 55 | 30 | 66 |

| LF-62/45 | 450 | 62 | 55 | 28 | 66 |

| LF-54/52 | 520 | 54 | 55 | 26 | 66 |

| LF-46/63 | 630 | 46 | 55 | 24 | 66 |

| LF-38/75 | 750 | 38 | 55 | 22 | 66 |

| LF-32/85 | 850 | 32 | 55 | 20 | 66 |

| LF-26/110 | 1100 | 26 | 55 | 18 | 66 |

Cleaning accessories include pressure regulating valve, one way relief valve and high-pressure hose.

- Regulating valve(picture 4) To regulate the output pressure and constant pressure of pump.

Turn the nut in clockwise, the output pressure of pump comes up; otherwise comes down. In pressure testing trial, should turn the regulate nut in anticlockwise and open the pressure regulating valve when the system pressure comes to a set pressure to discharge the output pressure. When the customer need the constant pressure ,should turn the pressure to a setup pressure and lock down the nut.

3,Cleaning accessories

Cleaning accessories include pressure regulating valve, spray gun and high-pressure hose.

(1) Pressure adjusting valve: working principle (vide supra)

While washing, turn pressure to working pressure and lock the locknut.

(2)Spray gun:

Spray gun is the switch-controlling component that is connected to the outlet of pressure regulating valve by high-pressure hose. Press or loose the trigger to control jet flow.

三,Assembly and operation manual

1,Install accessories and pressure gauge

Mount on high pressure hose and spray gun, (for installation refer to picture ),. at this time, detach the plugs on the pressure regulating valve and fit with pressure gauge. Connect the pressure-regulating valve to spray gun, then seal each bolted connections with red copper gasket.

2, Operation guide

- Preparation before initial use

- Apply oil into the wheel box until oil surface reaches the middle of oil leveler. Meanwhile, add lubricant into the front end of tank..

Lubricant type: N46﹟machine oil( air compressor oil or hydraulic oil with similar viscosity coefficient)

- Check screwed connections, and tighten them if necessary.

- Check whether the insulated parts of electric motor and starting vessel meet electric appliance standards. For your safety, earth the wire reliably.

- Connect the inlet junction panel on the case to water source (clean and sufficient) by pipe.

- xplosion Proof Pressure Washers High Pressure Pump Unit For Sewage And Slurry

-

Applications of High pressure washer:

Like :1.using in cleaning the Aluminium plant Hardened bauxite dust on mills, filters, floors, tanks, sumps and sewers. With preesure 350bar – 2800bar

2.Using to wash Aviation Expansion joints, grease, rubber and hydraulic fluids on runways. With pressure 690bar - 1400bar

3. Using to wash the Breweries Yeast, sediments and fermentation residues on vats, pipe and facilities. With pressure 200bar – 2800bar

4. Using to Cement plant Remove dirt, grease and product build up on grates, floor, external piping, bins, walls, hopper cars and

handling equipment. With pressure 200bar – 690bar

5. using to wash Chemical processing Chemicals from boiler tubes, tanks, valves. evaporators, heat exchangers, tube bundles, vessels,

reactors and storage tanks. With pressure 350bar – 2800bar

6. using to Construction Concrete demolishing, exposing steel-bars, cutting concrete and steel bars. With pressure 350bar – 2800bar

7.using to Distilleries Cleaning of heat exchanger, boiler tubes, vats and pipe lines. With pressure 600bar- 2800bar

8.using in washing the Food processing Grease, fats, oil and dough from ovens, mixers, conveyors and facilities. With pressure 200bar – 1000bar

9.using to clean the Foundries Removal of deposits, metal oxidation, ceramic & sand core materials for casting. With pressure 1000bar – 2800bar

10.using in Highway Maintenance Cleaning of grease, vegetation, mud tar, cement or asphalt on vehicles & machinery. Removal of

expansion joints, paint strips and concrete demolishing on road bridges. With pressure 350bar – 2800bar