2600bar High Pressure Water Blasting Machine High Pressure Cleaner

-

Highlight

2600bar High Pressure Cleaner

,2600bar Water Blasting Machine

,High Pressure Water Blasting Machine

-

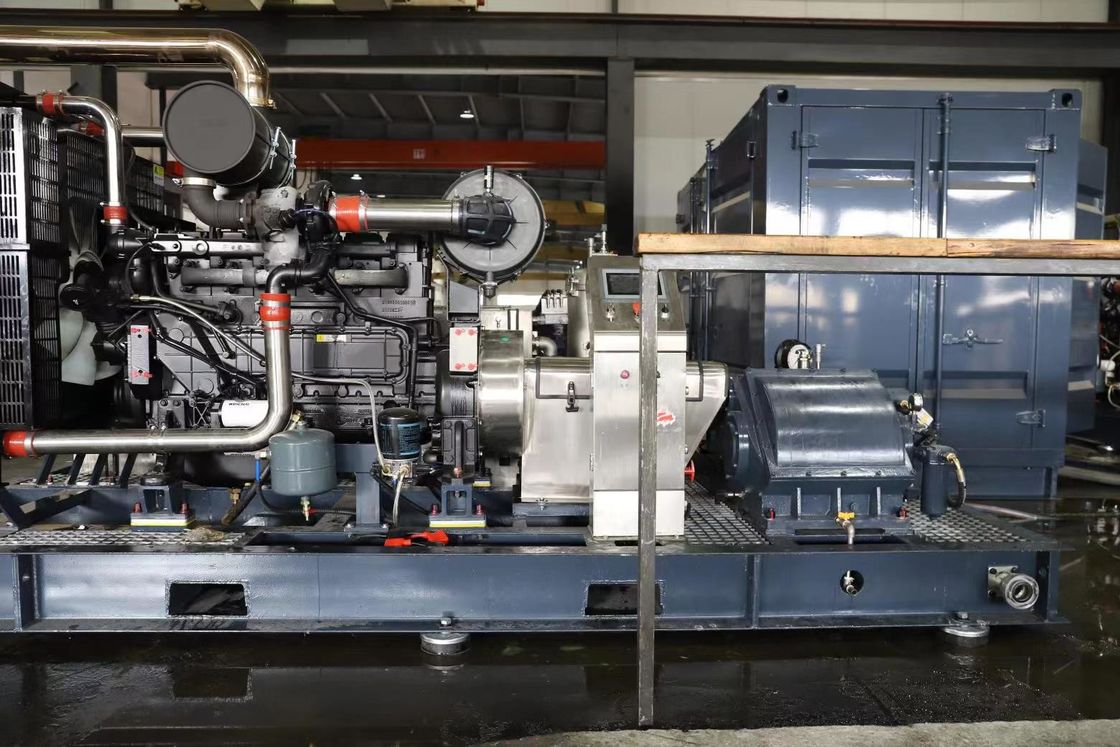

Product Name2600bar High Pressure Water Blasting Machine High Pressure Cleaner

-

ColorAccording To Customer Request

-

Max.pressure2600bar

-

Water Flow100L/min

-

FuelElectricity Or Diesel

-

TypeHigh Pressure Cleaning

-

Power700HP

-

Place of OriginChina

-

Brand NameLIFENG

-

CertificationISO9001:2018

-

Model NumberSD-100/260

-

Minimum Order Quantity1 unit

-

Price10000-30000 USD

-

Packaging DetailsPacked by non-fumigation wooden box

-

Delivery Time25 working days

-

Payment TermsT/T, Western Union, MoneyGram

-

Supply Ability100 units per month

2600bar High Pressure Water Blasting Machine High Pressure Cleaner

2600bar High Pressure Water Blasting Machine High Pressure Cleaner

Details:

1.The product and the pulse are more stable than the five plunger design

2.Cross head is made by the Babbitt hard alloy.it has a long working life for industrial design.

3.Hydraulic end pump head is made by the hard alloy 40Cr.it can work continuously for cleaning jobs.

4.All hydraulic end is desgined for easy uninstall,so it is easy to fix when the parts broken.

5.For some outdoor use purpose,we can make it driven by the diesel engine or the gasoline engine.

6.Longer warranty time reaches 2 years.

7.External all-round multi-point forced lubricate oil system.

2600bar High Pressure Water Blasting Machine High Pressure Cleaner

Characteristics as below:

![]()

Product Description

Industrial high pressure hydro blasting machine is an equipment which is used to clean the surface of objects,the machine with high pressure water jet by means of a power device. It can peel off the dirt ,wash it away to achieve the purpose of cleaning the surface of objects. Because it uses high-pressure water column to clean dirt, high-pressure cleaning is also recognized as the most scientific, economic and environmentally friendly cleaning method in the world compare to the chemical cleaning.

The purpose of a water pump is to move water not containing suspended solids or particulates. Water pumps handle ground water, potable and salt water. High Pressure water pumps are widely used in water jetting applications.

Water jetting equipment using high pressure water pumps is used to direct high pressure water streams against material to clean or cut it. The streams of water released by water jetting and water blasting equipment is normally 5,000 PSI to 40,000 PSI. In an efficient water jetting system, pressure is vital consideration. Typically, hardened deposits respond better with high pressure water pumps, and softer materials are best removed with lower flows.

Water jetting and water blasting equipment is used for cleaning or demolition of products made of metal, wood, concrete, stone, plastic, glass or other building materials.

Specific components within a water jetting system include abrasive injectors, pressure generators, blast cabinets or booths, water guns, and water tanks. Abrasive injectors can convert a water jetting system into an abrasive blaster. The injection or metering system controls the amount of abrasive pushed into the air stream. In large systems, the delivery system and injection system may be separate components. Pressure generators increase the pressure of the carrier fluid (water or air). Plunger-type intensifier pumps are commonly used to generate high pressure water for water jet cutting, wet or water abrasive blasting and non-abrasive pressure washing or rinsing.

Standard and custom high-pressure Hydro Laser units are built with Tritan triplex or quintuplex pumps. Quintuplex and triplex pumps are positive-displacement reciprocating pumps that are configured with three or five plungers. High pressure water pumps used in high pressure water blasting and water jetting operations.

These hydro laser high-pressure water pumps can be driven by electric motor, diesel, or gasoline engine. A complete system package can be ready to easily take care of your next difficult cleaning job.

Optional Equipment:

Hydro Dump Gun - Constructed Entirely of Stainless Steel.

Jet Tips - Stainless Steel: Two (2) Straight Round Pattern or Two (2) Flat Fan Pattern.

Discharge Gauge.

Relief Valve - Stainless Steel Construction and Adjustable.

Discharge Hose - 50 ft Section

Units are mounted on trucks, trailers, or skids.

A variety of accessories are available to adapt to specialized cleaning requirements. Hoses, Cleaning Guns, Jet Cleaning Heads: Single Orifice, Multi Orifice, Flat Fan, Self-Propelled

Fulfill a multitude of cleaning applications:

Water Jetting, Water-Chemical Cleaning, Water-Sand Cleaning, Water Power Sewer Cleaning & Flushing

Features

-

This machine is made up of mainly by high pressure reciprocating pump, power units and cleaning accessories etc.

1) High pressure reciprocating pump: the pump is horizontal triplex plunger pump, driven by electric motor, made up of by power end and fluid end.

- Power end: it is made up of by belt pulley(couplings), crankshaft and connecting rod etc. Electric motor or diesel engine,or gasoline engine driven the crankshaft and reduces its speed, and crank link mechanism will change whirling movement to straight line reciprocating movement.

- Fluid end: it is made up of by plunger set, high pressure cylinder, pump body and water input and output valves etc. High pressure cylinder is fixed on crankcase while connecting rod drives plunger to do reciprocating movements, which make volume in cylinder do cyclical change. When plunger is in-sucking stroke, the volume in cylinder increases, water output valve closes, local vacuum is formed. Working media enter into high pressure cylinder by going against water input valve under high atmospheric pressure. When plunger is in discharging stroke, water input valve closes, and plunger transfer the working media to pump body by water output valve, to pressure regulating valve, finally to high pressure spray gun by high pressure hose.

-

The purpose of a water pump is to move water not containing suspended solids or particulates. Water pumps handle ground water, potable and salt water. High Pressure water pumps are widely used in water jetting applications.

Water jetting equipment using high pressure water pumps is used to direct high pressure water streams against material to clean or cut it. The streams of water released by water jetting and water blasting equipment is normally 5,000 PSI to 40,000 PSI. In an efficient water jetting system, pressure is vital consideration. Typically, hardened deposits respond better with high pressure water pumps, and softer materials are best removed with lower flows.

Water jetting and water blasting equipment is used for cleaning or demolition of products made of metal, wood, concrete, stone, plastic, glass or other building materials.

Specific components within a water jetting system include abrasive injectors, pressure generators, blast cabinets or booths, water guns, and water tanks. Abrasive injectors can convert a water jetting system into an abrasive blaster. The injection or metering system controls the amount of abrasive pushed into the air stream. In large systems, the delivery system and injection system may be separate components. Pressure generators increase the pressure of the carrier fluid (water or air). Plunger-type intensifier pumps are commonly used to generate high pressure water for water jet cutting, wet or water abrasive blasting and non-abrasive pressure washing or rinsing.

Operating process

Start the motor under the spray gun is closed and waiting the motor is working normally, and then begins other operation. At this time, the regulating valve is unloading. Run it for 5 minutes and examine the pump (whether it is normal), the pressure of the oil should between 0.3Mpa and 0.6Mpa.If its sound is normal and discharging media is not obviously fluctuating, we can put the trigger of the spray gun and regulate the pressure regulating valve to the requested cleaning pressure and then lock the nut, use the spray gun to clean towards the objects cleaned by the washer. At this time, spray gun is under the condition of high pressure jet.

When finishing the cleaning work , loose the trigger and unload the spray gun and meanwhile anti-clockwise loose the pressure regulating valve hand wheel and the main set operates under the condition of unloading and then stop.

GUARANTY OF QUALITY

We offer products of our own design and production and we guarantee it is high quality. A quality control of performed works is one of the main advantages of our Company. Important components of effective work: high qualification of our engineers, strict implementation of technical standards, application of quality materials, use of the most modern equipment and software.

Strict materials incoming (quality) control and acceptance tests

Laboratory and bench testing

100% compliance with technology, international standards

Application of the most modern high-tech QC tools

All manufactured equipment passes bench and field tests

International quality level

Positive feedbacks from our customers

It is extremely important for us that all our customers are 100% satisfied with the quality of our work!

INNOVATIVE AND TECHNOLOGY LEADER

Our mission is to continuously innovate, develop and offer the most efficient equipment for our customers.

Own design office

Technology Innovation Center

The of Companies employs more than 100 qualified and experienced engineers, designers and technicians

Own laboratory and test benches

Operative analysis and adjustment of design.

Applications

The pumps are widely used in oil refinery pipes cleaning, heat exchangers pipes cleaning, ship hull cleaing,oil paitings removing,rust removing,etc.

Meanwhile, our pumps also can be used for the fuel pipelines pressure testing,gas steel bottles explosion pressure testing,all kinds of the tubes pressure explosion testing, and so on.

![]()

90kw Hydro Blasting Equipment Industrial Water Jet Cleaner Machine 800bar

Diesel Industrial High Pressure Washers High Pressure Washing Machine For Pipelines Cleaning,This equipment needs to use a backflush nozzle to go inside to the pipes.the nozzles should be smaller than the heat exchangers pipes.

when start the high pressure cleaning machine,the backflush nozzles can go into the pipes itself by the water jet push power.

then the nozzles water jet can clean the inside of the pipes.

As a 40 years manufacturing factory,we have many foreign customers who came to our factory to visit.

some of the photos as below:

![]()

![]()

![]()

Applications:

it is widely used in ship cleaning,oil removing,fuel pipeline cleaning in refinery fields.

![]()

some foreign customers give us comments below:

![]()

![]()

FAQ

2600bar High Pressure Water Blasting Machine High Pressure Cleaner

Q1. What about the lead time?

A: 20 working days for mass production.

Q2. Do you have any MOQ limit for the product order?

A: Low MOQ, 1pc.

Q3. How do you ship the goods and how long does it take to arrive?

A: Ship by sea shipping.

Q4. How to proceed an order for the product?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly:we sign a contract

Fourthly We arrange the production.

Q5. Is it OK to print my logo on the product?

A: Yes. Please inform us formally before our production.

Q6: Do you offer guarantee for the products?

A: Yes, we offer 1 years warranty to our products.